The CTRG explained

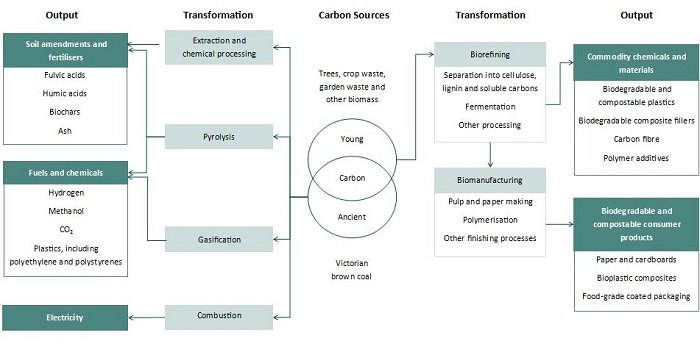

We see carbon as feedstock- carbon based materials surround us and are essential to our lives. The following diagram offers an overview of the way we understand carbon and its uses.

The centre of the diagram shows how young and ancient carbon overlap as key resources for the CTRG. Adding value to carbon resources occurs in two ways: through chemical extraction and processing, and biomanufacturing.

The right side of the diagram shows how young carbon, or biomass, is preferably converted into soluble carbon, fibres, lignin and cellulose (refined sugars) during the biorefining processes of fermentation and separation. Soluble sugars become biopolymers, fibres become biodegradable composite fillers, lignin becomes carbon fibre. Cellulose becomes nano-cellulose to be turned into composite materials such as paper, biopolymer composites and coatings. These products become commodity chemicals and minerals and include biodegradable and compostable plastics, biodegradable composite fillers, carbon fibre and polymer additives. The biomanufacturing stage involves finishing processes such as pulp and paper making and polymerisation which produces biodegradable and composite consumer products such as paper, cardboards, bioplastic composites and food-grade coated packaging.

The left side of the diagram explains how ancient carbons such as coal are more suited to thermal processing and are thus transformed by chemical extraction and processing. Pyrolysis and extraction and chemical processing produces biochars, ash and soil amendments of fulvic and humic acids. Pyrolysis and gasification can lead to fuels and chemical such as hydrogen, methanal, carbon dioxide and polymers. Finally, combustion leads to electricity. Subsequently, carbon is at the very centre of the CTRG because of its ability to be used in such diverse ways.

Carbon is at the centre of the CTRG. This diagram has been designed to describe how we understand young and ancient carbon. Gippsland and Victoria are rich in both young, renewable carbon as well as ancient carbon. Young carbons include actively growing crops and plantations, and waste biomass. Victorian brown coal is a massive resource of ancient carbons, having been formed over many millions of years from ancient forests and swamps. Both young and ancient carbons have similar origins in plants, trees and other living matter and, therefore, share some chemical properties and structures. Some traditional uses of ancient carbons are applicable to young carbons and vice versa. However, there are many differences between young and ancient carbons and industries have been developed to make the most of these differences. We are interested in both carbon sources and are keen to support the development of industries based on young carbons in areas that have been traditionally dominated by ancient carbons.

The key benefits of ancient carbon like the Victorian brown coal or lignites, shown in the above picture, include it being a massive resource compared to similar global deposits, it is cheap and easy to mine, it is clean as it is low in impurities like sulfur which causes acid rain when combusted, and it is reactive compared to black coals. Victorian brown coal cannot be transported without pretreatment as it combusts spontaneously, and it has a high water content. This water must be evaporated during combustion, which wastes a lot of energy.

Combustion involves burning to create electricity and is the most well-known use of Victorian brown coal. Energy recovery and use is generally the lowest cost and lowest return for carbon resources. One benefit of combustion is that it is relatively simple. However, a well-known problem with combustion is the CO2 produced as part of combustion being expensive to capture for reuse or storage.

CO2 is an inevitable product when using carbon resources to produce energy – we even produce CO2 from the food we eat. PCC (post-combustion CO2 capture) has the potential to reduce the economic and social costs of the transition from traditional energy production (especially fossil-fuel combustion) to newer, renewable energy sources. More recently, PCC is being discussed as a way to actively remove CO2 from the atmosphere. The CTRG contributed to global research efforts to understand possible difficulties with adapting PCC technology to coal-fired power stations. Commercial-scale PCC is now operating successfully at a Canadian coal-fired power station and more information can be found here: https://ccsknowledge.com/.

Once separated from flue gases or other industrial gases, CO2 must be used or stored safely. Traditional uses for CO2 are limited but there is a lot of interest in producing fuels, chemicals, and building products and other materials from CO2. In the short- to medium-term, it remains unlikely that all the CO2 that needs to be removed from the atmosphere can be converted to useful products. Storing CO2 in geological formation remains an active area of research and development.

PCC Solvent Degradation Rig: | Solvent Degradation Colour Change During PCC: |

Gasification and pyrolysis are both based on high temperature, low oxygen conversion of carbons (young and old) to liquids and gases. Gasification produces a syngas that can be used to produce most of the chemicals currently produced by natural gas. These products can include tars, liquid fuels (similar to petrol, diesel and heavy fuels for shipping and heating), and chemicals. Hydrogen is an important aspect of the gasification and pyrolysis process and could play a significant role in Australia’s future energy mix. The ongoing HESC project uses Victorian brown coal to produce hydrogen. CO2 is a product, but it is easier to capture than the CO2 produced by combustion because it is produced at a higher concentration and higher pressure. Over the life of gasification/pyrolysis and use of the products, a similar amount of CO2 produced will be similar to that produced during combustion.

The most exciting use for coal is soil amendments including humates and fulvates which are used widely in high intensity greenhouse production. Omnia is a company that sells humates (produced from Victorian brown coal in Morwell) around the world. Andrew Hood’s PhD project fits in here perfectly by examining the feasibility of upgrading and utilising a wider range of coals to cost-effectively produce humates. The potential to convert humates to advanced carbons including graphenes and carbon fibre is an exciting part of research into this area. Soil amendments such as biochars can be produced from young carbon too – including municipal solid waste.

Advantages of young carbons include that they are often renewable (including plantation crops or industrial hemp) or byproducts of existing processes (including municipal solid waste, pulping waste streams – e.g. WTIF Biopathways project). However, sources of young carbon are often spread over a wide geographical area and the costs of transport to a central processing site are often prohibitive. Unlike ancient carbons, young carbons are usually heterogeneous (e.g. leaves are very different to seeds, stalks and logs). The first step of young carbons is often a separation step. In many cases, young carbons can be separated into lignins, fibres, cellulose and soluble carbon such as sugars.

Biorefinery and circular economy concepts focus on using as much of carbon resources as possible by creating multiple products. Early generation biorefineries (e.g. pulp and paper mills) typically aim to create as much pulp and paper from their feedstocks as possible. Some byproducts (often turpentines and resins) may be refined for sale but up to two-thirds of the incoming logs are often treated as waste.

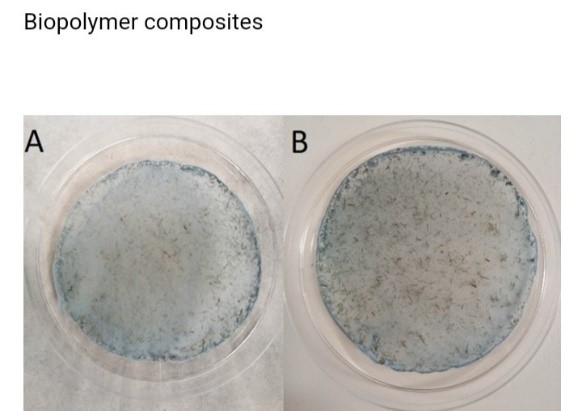

New generation biorefineries use advanced manufacturing technologies to generate multiple products from their feedstocks. For example, each component of the incoming logs could be separated and converted to a saleable product. This might mean converting the cellulose to paper (similar to traditional pulp and paper mills), soluble carbons to bioplastic precursors (e.g. fermentation to succinic acid), and lignin to composites (especially biopolymer composites). Many other products are also possible and some that we are interested in include refining natural fibres for use in biopolymer composites and converting lignin to carbon fibre or graphene.

|  |

These are some of the ways the CTRG sees carbon-based industries evolving into the future. We are interested in considering and expanding ideas around economic and environmental sustainability and hope to continue working with organisations such as the ACI and CSIRO in these areas.